Clean the coffee capsule filling machine regularly to remove any coffee residue or debris that may accumulate during the filling process. Use appropriate cleaning agents and follow the manufacturer’s instructions for cleaning.

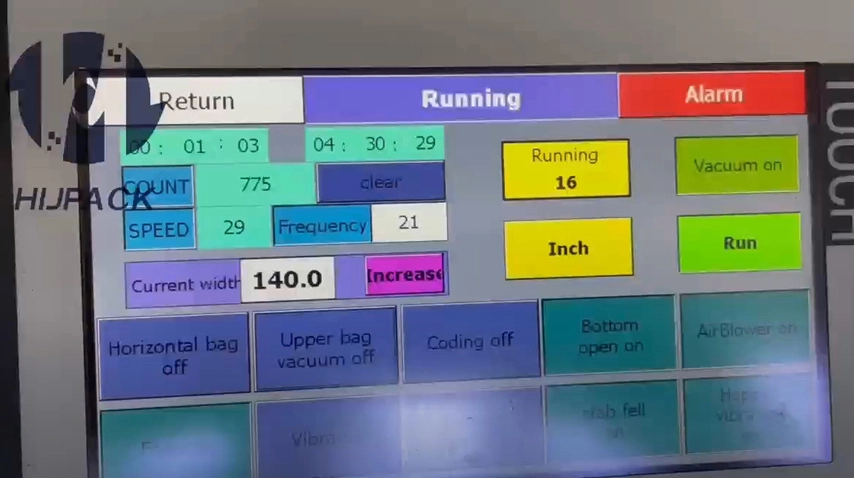

A coffee capsule filling machine also named coffee capsule packing machine, is a type of packaging machine specifically designed for filling coffee capsules or pods. The coffee capsule packaging machine automates the process of filling individual capsules with ground coffee or instant coffee. These automatic coffee capsule filling and sealing machines are highly efficient and can handle high volumes of coffee capsules, allowing for faster production and increased productivity. HIJPACK packaging machinery manufacturer offers a variety of coffee capsule packing machines, coffee capsule powder filling machines, k cup filling machines, nespresso capsule filling machine, nespresso capsule coffee machine and more in small, medium and large sizes. If you want to know more about automatic coffee capsule filling machines and coffee capsule filling machine prices, please do not hesitate to contact HIJPACK package making machine.

English

English français

français italiano

italiano Español

Español português

português العربية

العربية