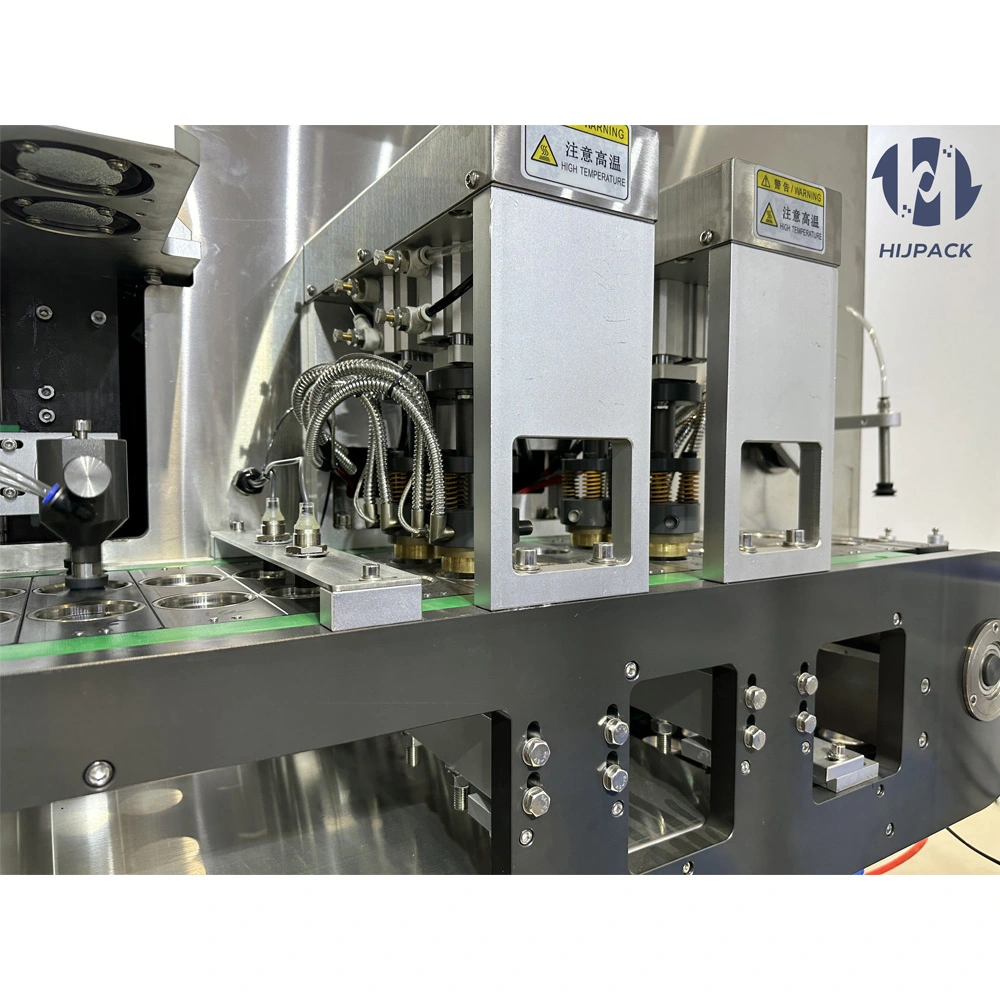

CF120 K Cup Coffee 2 Lanes Filling and Sealing Machine is a versatile piece of equipment designed for canning, sealing, and capping coffee capsules. It is capable of handling two rows of capsules simultaneously, increasing productivity and efficiency. This coffee capsule powder filling machine is equipped with advanced technology and features, allowing for precise and consistent canning, sealing, and capping of the capsules.

The highest production speed of the machine can reach 4800 cups per hour, with an error of no more than 0.15g for filling volume.

The machine has a compact structure and a short time for filling and sealing, and it can handle complex sealing forms.

It ensures that the filling process is not contaminated, as all materials in contact with the product are made of 304 stainless steel and have undergone a full polishing treatment.

The filling components are easy to disassemble, such as the barrel valve body and the screw feeding head, making it easy to clean, disinfect, and sterilize.

During the filling process, the feeding nozzle can press against the cup opening, ensuring effective filling and preventing material from sticking to the aluminum opening and affecting the sealing.

The machine is equipped with a nitrogen device, with a nitrogen injection port in the barrel, and the entire machine is sealed with organic glass, allowing the sealing process to be carried out in a nitrogen-filled environment.

English

English français

français italiano

italiano Español

Español português

português العربية

العربية