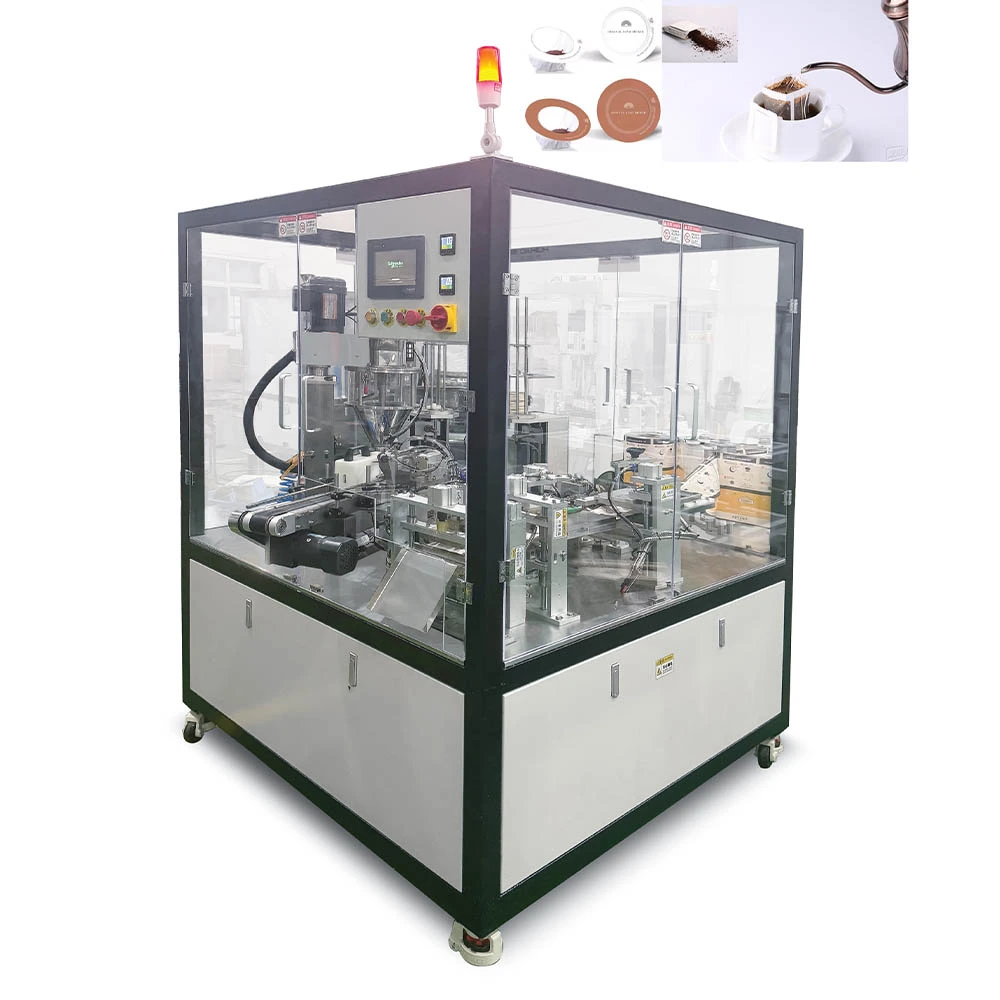

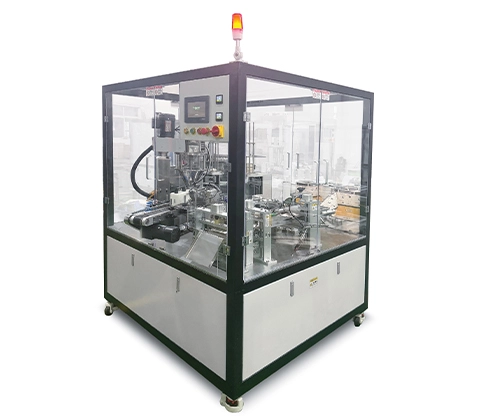

HIJPACK is a trusted coffee packaging equipment manufacturer and supplier, with R&D, manufacturing and service in one, dedicated to providing intelligent packaging solutions for all categories such as coffee capsules, coffee beans, coffee powder, drip coffee, tea leaves, etc.

"Let every cup of coffee be presented perfectly starting from packaging!"

Nespresso Coffee Capsule Machine, K Cup Filling and Sealing Machine, Dolce Gusto Capsule Filling and Sealing Machine,Powder Filling Machine, Buckle Cup Filling Machine, Drip offee Packaging Machine, Coffee Round Packaging Machine, Liquid Filling Machine, Granule Packaging Machine, Pre-made Bag Packaging Machine, Stick Pouch Packing Machine, Triangle Bag Packacging Machine, Tea Packing Machine,Automatic Packing Machine,etc.

English

English français

français italiano

italiano Español

Español português

português العربية

العربية